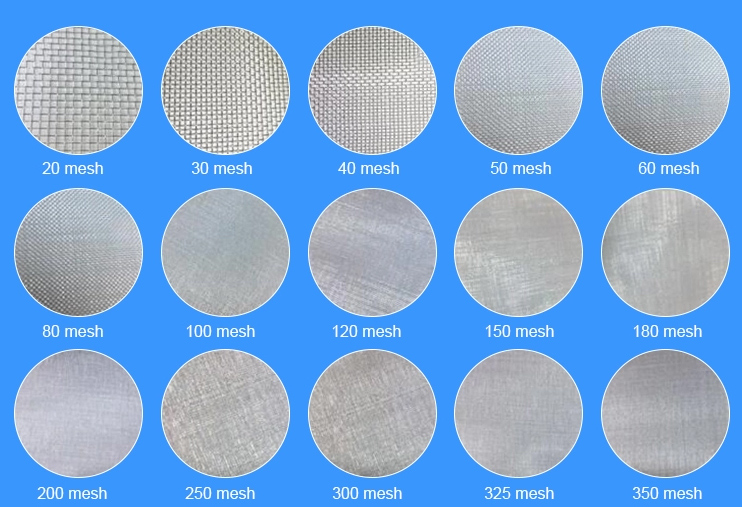

| Mesh | Wire Diameter(mm) | Aperture(mm) |

| 2 | 1.80 | 10.90 |

| 3 | 1.60 | 6.866 |

| 4 | 1.20 | 5.15 |

| 5 | 0.91 | 4.17 |

| 6 | 0.80 | 3.433 |

| 8 | 0.60 | 2.575 |

| 10 | 0.55 | 1.990 |

| 12 | 0.50 | 1.616 |

| 14 | 0.45 | 1.362 |

| 16 | 0.40 | 1.188 |

| 18 | 0.35 | 1.060 |

| 20 | 0.30 | 0.970 |

| 26 | 0.28 | 0.696 |

| 30 | 0.25 | 0.596 |

| 40 | 0.21 | 0.425 |

| 50 | 0.19 | 0.318 |

| 60 | 0.15 | 0.273 |

| 70 | 0.14 | 0.223 |

| 80 | 0.12 | 0.198 |

| 90 | 0.11 | 0.172 |

| 100 | 0.10 | 0.154 |

| 120 | 0.08 | 0.132 |

| 140 | 0.07 | 0.111 |

| 150 | 0.065 | 0.104 |

| 160 | 0.065 | 0.094 |

| 180 | 0.053 | 0.088 |

| 200 | 0.053 | 0.074 |