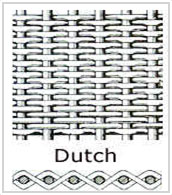

Reversed dutch weave mesh belt is produced of more thin warp wires and fewer but large weft wires.Thinner and closer warp wires together with the weft wires form triangular shapes transversal openings.This structure increase the degree of stability and optimal resistance to high pressure.

Reversed dutch weave mesh belt is produced of more thin warp wires and fewer but large weft wires.Thinner and closer warp wires together with the weft wires form triangular shapes transversal openings.This structure increase the degree of stability and optimal resistance to high pressure. Material: stainless steel wire 304, 316 or 316L.

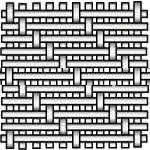

Roll width: 67mm, 95mm, 97mm, 127mm, 133mm, 150mm, 157mm,300mm, 400mm, etc. Roll length: 10m, 20m,etc. Weaving methods: reverse plain dutch weave, reverse twill dutch weave. Packing:with paper tube inside to reduce loading pressure,then wrapped with moisture paper outside.then placed in wooden case.| Reverse Dutch Weave Belts | |||

| Weave of Type | Mesh/Inch | Wire Diameter mm | Nominal Micron μm |

| TRD | 48 x 10 | 0.50 X 0.50 | 400 |

| TRD | 72 x 15 | 0.50 x 0.50 | 300 |

| TRD | 132 x 14 | 0.35 x 0.45 | 200 |

| TRD | 132 x 18 | 0.35 x 0.44 | 180 |

| TRD | 152 x 24 | 0.27 x 0.40 | 160 |

| TRD | 152 x 30 | 0.27 x 0.30 | 130 |

| RPD | 250 x 40 | 0.15 x 0.25 | 90 |

| RPD | 260 x 40 | 0.15 x 0.27 | 125 |

| RPD | 280 x 70 | 0.089 x 0.21 | 45 |

| RPD | 325 x 39 | 0.13 x 0.24 | 55 |

| RPD | 600 x 125 | 0.043 x 0.12 | 20 |

| RPD | 720 x 150 | 0.035 x 0.107 | 15 |

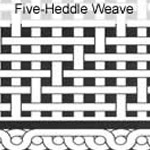

Five heddle mesh

| Meshes per inch Warp x Weft(mesh) | Wire Diameter (mm) | Aperture (mm) Warp x Weft | Open Area % | Weight (kg/m2) |

| 108 X 59 | 0.160 | 0.075 X 0.271 | 20 | 1.07 |

| 110 X 60 | 0.160 | 0.071 X 0.263 | 19 | 1.09 |

| 38 X 38 | 0.150 | 0.518 X 0.518 | 60 | 0.43 |